Innovation in Emission Control: The Role of TESWX in Clean Air Technology

In today's society, where environmental protection and sustainability are growingly vital, the reduction of harmful exhaust gases is a crucial focus for diverse industries. Vehicles, industrial machinery, and power generation facilities produce emissions that have adverse consequences for air quality and the climate. The need for sophisticated and impactful emission control systems is, therefore, more pronounced than ever. Companies like TESWX are at the forefront of this technological revolution, offering innovative solutions such as the "SCRF Selective Catalytic Reduction Filter", "Metallic TWC Catalysts", "Catalyst Coating Line", and the "Catalytic Diesel Particle Filter". These technologies are designed not only to meet the strictest international emission standards but also to create a long-term future for everyone. An in-depth look at TESWX's expertise reveals how their products and services contribute to a cleaner environment and more efficient industrial processes.

The Power of the SCRF Selective Catalytic Reduction Filter

The SCRF (Selective Catalytic Reduction Filter) technology represents a notable leap forward in the reduction of nitrogen oxides (NOx) from exhaust gases. NOx is a major pollutant contributing to acid rain, smog, and various respiratory problems. The SCRF is an combined system that merges the function of an SCR catalyst and a diesel particulate filter into a single, compact unit.

How does TESWX's SCRF technology work?

Reductant Injection: Before exhaust gases reach the filter, a reductant, typically a urea solution (AdBlue), is injected into the exhaust stream.

Chemical Reaction in the Catalyst: In the SCR section of the SCRF, the reductant reacts with the NOx gases. This reaction converts harmful nitrogen oxides into harmless nitrogen (N2) and water (H2O).

Particulate Filtration: The filter section of the SCRF then captures fine particulate matter (soot particles) from the exhaust gases. These soot particles are periodically burned off (regenerated) to keep the filter clean.

Optimal Efficiency: By combining SCR and particulate filtration in one unit, the SCRF offers a excellent efficiency in removing both NOx and particulate matter, permitting vehicles and industrial systems to meet the strictest emission standards.

The SCRF Selective Catalytic Reduction Filter technology from TESWX is designed for longevity and optimal operation, making it an optimal solution for heavy-duty vehicles, off-road machinery, and stationary engines. Its compact design also facilitates easier integration into current exhaust systems, offering a budget-friendly and reliable solution for emission control. TESWX's commitment to continuous innovation ensures that their SCRF solutions remain at the forefront of clean air technology, helping industries globally to reduce their environmental footprint.

Metallic TWC Catalysts: A Core Component of Clean Combustion

Metallic TWC (Three-Way Catalytic) Catalysts are essential for gasoline engines, playing a key role in simultaneously reducing three major pollutants: carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx). Unlike traditional ceramic catalysts, metallic catalysts offer multiple distinct advantages that make them a preferred choice for current emission control systems.

Key benefits of Metallic TWC Catalysts from TESWX include:

Improved Heat Transfer: Metallic substrates have better thermal conductivity, allowing them to heat up faster and reach their optimal operating temperature more quickly. This is essential for reducing emissions during the cold-start phase, which is when a considerable portion of pollutants are emitted.

Higher Cell Density: Metallic substrates can be designed with a higher cell density (cells per square inch) compared to ceramic counterparts, offering a more expansive surface area for catalytic reactions. This leads to better conversion efficiency and more effective pollutant reduction.

Enhanced Durability: Metallic catalysts are inherently more robust and resistant to mechanical shock and thermal stress. This translates into a longer lifespan and higher reliability, particularly in demanding operating conditions.

Lower Pressure Drop: The optimized flow channels in metallic catalysts result in a lower pressure drop across the catalyst, which can contribute to improved engine performance and fuel efficiency.

TESWX leverages its skill in catalyst design and manufacturing to produce premium Metallic TWC Catalysts that meet the demanding requirements of Metallic TWC Catalysts the automotive industry. These catalysts are an fundamental part of ensuring that gasoline-powered vehicles operate as cleanly and efficiently as possible, contributing to better air quality and a healthier environment.

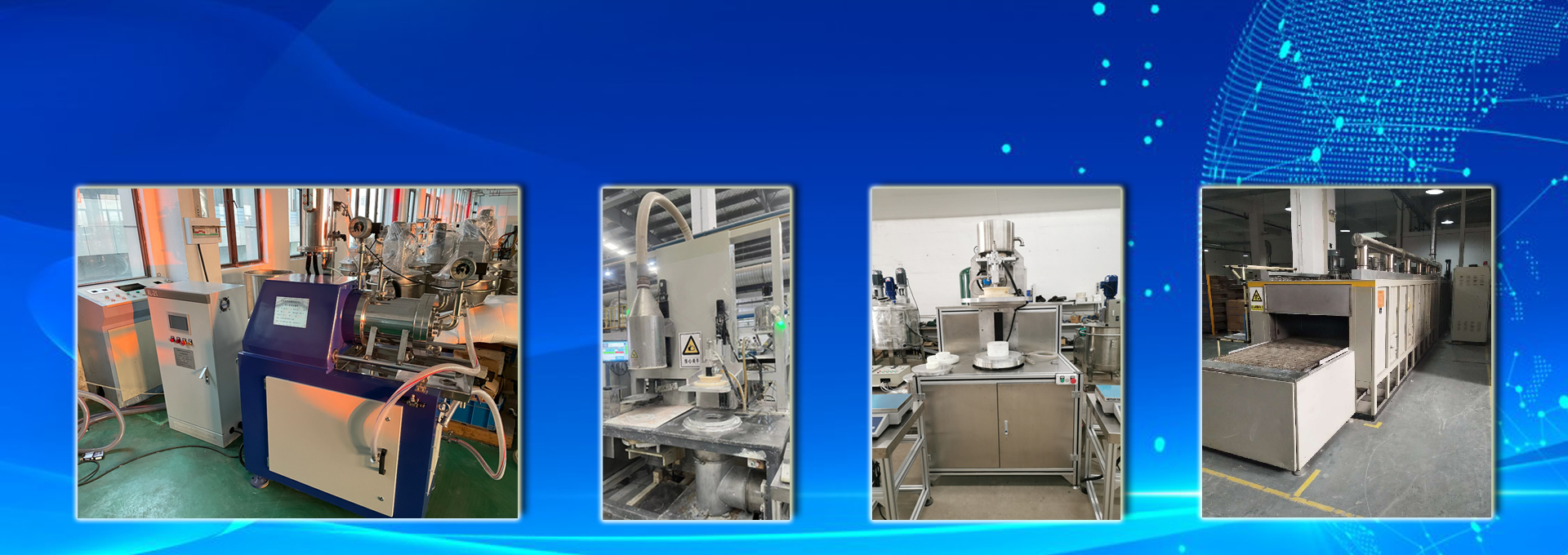

Catalyst Coating Line: The Heart of Catalytic Production

The performance of any catalyst hinges significantly on its coating. A "Catalyst Coating Line" is a dedicated manufacturing facility where the active catalytic material is precisely applied onto the substrate (either ceramic or metallic). This process is essential for ensuring the efficiency and longevity of the final catalyst product.

TESWX operates a advanced Catalyst Coating Line, incorporating leading-edge technologies and processes to achieve optimal results:

Precision Coating: The coating process requires extreme precision to ensure a uniform and controlled layer of catalytic washcoat. This layer contains precious metals (like platinum, palladium, and rhodium) and support materials that facilitate the chemical reactions.

Automated Systems: Modern coating lines utilize automated systems for accurate application, minimizing variations and maximizing consistency across batches. This automation also contributes to higher production efficiency and reduced manufacturing costs.

Quality Control: Strict quality control measures are implemented at every stage of the coating process, from raw material inspection to final product testing. This ensures that every catalyst meets the required performance criteria and emission standards.

Research and Development: TESWX continuously invests in research and development to improve its coating formulations and processes. This includes developing new washcoat technologies that enhance catalyst performance, reduce precious metal loading, and extend catalyst lifespan.

The Catalyst Coating Line at TESWX is a testament to their commitment to innovation and quality. It allows them to produce top-tier catalysts, including SCRF and Metallic TWC Catalysts, that are crucial for diverse applications, from automotive to industrial emission control. This sophisticated manufacturing capability underpins TESWX's ability to deliver cutting-edge solutions for a cleaner future.

Catalytic Diesel Particle Filter: Mastering Soot Emission Control

The "Catalytic Diesel Particle Filter" (CDPF) is an crucial component in contemporary diesel exhaust systems, specifically designed to capture and eliminate harmful particulate matter (PM), often referred to as soot. Diesel engines, while fuel-efficient, historically have been key contributors to PM emissions, which pose considerable health risks and contribute to air pollution.

The function and benefits of TESWX's Catalytic Diesel Particle Filter are:

High Filtration Efficiency: CDPFs are highly effective at capturing over 90% of the particulate matter from diesel exhaust. This markedly reduces the emission of black smoke and ultrafine particles.

Integrated Catalytic Function: Unlike basic particulate filters, a catalytic diesel particle filter has a special coating that assists in the regeneration process. This catalytic coating lowers the temperature required for soot combustion, enabling passive regeneration to occur during regular driving conditions.

Reduced Need for Active Regeneration: Passive regeneration reduces the need for the engine to actively raise exhaust temperatures to burn off accumulated soot, which can save fuel and lower operating costs.

Enhanced Durability and Reliability: TESWX designs its CDPFs for peak longevity, ensuring dependable performance over the lifespan of the vehicle or equipment.

Compliance with Emission Standards: The CDPF is essential for diesel engines to meet growingly strict emission regulations (e.g., Euro 6, EPA Tier 4), ensuring that diesel vehicles can continue to operate in various markets.

By effectively controlling soot emissions, the Catalytic Diesel Particle Filter from TESWX contributes to cleaner urban air and improved public health. It exemplifies TESWX's dedication to groundbreaking and green solutions for diesel engine technology.

Conclusion: TESWX – Driving a Cleaner, Healthier Future

In an era defined by environmental consciousness and the urgent need for sustainable practices, the advanced emission control technologies developed by TESWX are more important than ever. Through their dedication to research, development, and precision manufacturing, TESWX provides essential solutions like the SCRF Selective Catalytic Reduction Filter, Metallic TWC Catalysts, advanced Catalyst Coating Lines, and Catalytic Diesel Particle Filters. These innovations collectively contribute to a meaningful reduction in harmful pollutants from numerous sources.

TESWX stands as a leader in the field, permitting industries internationally to meet and exceed rigorous environmental regulations, simultaneously enhancing performance and efficiency. By investing in these sophisticated technologies, businesses are not only complying with environmental mandates but are also actively participating in the creation of a cleaner, healthier future for everyone. The commitment of TESWX to pushing the boundaries of emission control technology is a testament to their vision for a more sustainable and environmentally responsible planet.